Thin oxide films for developing model materials for semiconductors, sensors and batteries

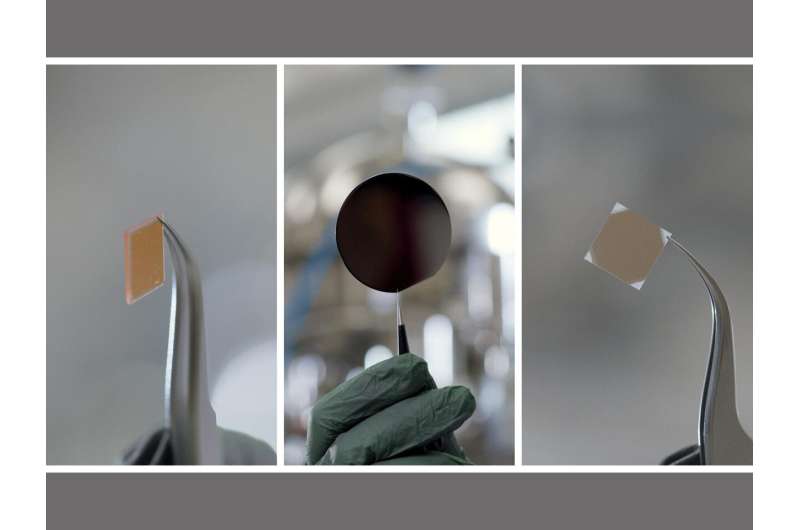

Thin oxide films grown at the Center for Energy Science allow researchers to study complex processes in controlled systems. Credit: Eddie Pablo, Pacific Northwest National Laboratory

One of the first attractions that welcomes visitors to the Pacific Northwest National Laboratory Energy Science Center (PNNL’s) is the window into the busy lab space. Fully equipped and researchers doing their job, the film growth lab overlooks the foyer. It contains a team that creates extremely thin and precise films using different materials.

On any given day, researchers including Yingge Du and Tiffany Kaspar could be developing materials for next-generation batteries, photocatalysts, electronics or nuclear reactors. “Our work focuses on understanding thin oxide movies at a atomic level“This knowledge allows us to learn why materials behave in certain ways, which we can use to create new materials with specific properties,” says Du. . For example, placing a few oxygen atoms below the surface of a semiconductor, such as silicon, changes the way electrons move in the complex oxide deposited on top.”

Thin oxide films are used in applications as diverse as semiconductor chips electric power to fuel cells that help store energy. These exceptional materials improve our lives in many ways. But making them can be a tough job.

Founded by Scott Chambers, a member of the PNNL Laboratory, the thin film team uses precise growth techniques to deposit selected elements onto the target crystal, one atom at a time. This level of control allows them to develop modeling systems that simplify complex realities, helping researchers understand the fundamental properties of materials. team has discovered unexpected conduction sources in oxides, showed how interfaces can control the behavior of materialsAnd used structural control to create previously unstable materials.

They also develop movies with specific and useful properties. Their approach ranges from modifying materials to change the way they interact with electricity to tweaking the surface of materials to make renewable fuels more efficient. The team manages a variety of projects that focus on these functional materials. Their expertise in film control allows them to create new films for use in energy conversion reactions, including converting water to hydrogen and oxygenand energy storage devices, with work exploring how the movement of ions affects battery materials.

“Our research covers a lot of different aspects of oxide materials,” says Kaspar. “We might be able to explore properties at the atomic scale one day and film a specific application the next day. It’s exciting to work extensively with these materials.”

The PNNL lab contains special equipment, customized to give researchers exquisite control over their films. The team worked directly with manufacturers to modify their devices, specifically targeting oxide films. Centralized revisions allow researchers to create intricate and meticulously crafted materials, which they then carefully study using other tools and techniques available within the Center. Energy Science and Department of Energy user bases.

“The PNNL team is a world-class team in oxide thin film development,” said Kelsey Stoerzinger, associate, Assistant Professor of Chemical Engineering at Oregon State University, and PNNL general appointee. . “Their impressive attention to detail, coupled with an innate curiosity about science, has led to many fruitful collaborations between our teams. We are always excited to work together. by measuring the electrochemical performance of such high-quality films.”

Understand the movement of lithium for a better battery

Many lab-grown membranes consist of multiple layers of different oxide materials. The areas where different materials come into contact, called interfaces, are some of the most important parts of a device like the battery. In the batteries that power modern electronics, the interface between moving lithium atoms and stationary electrodes is an important place where new structures form and existing materials. have been broken. This can lead to poor battery performance and eventually cause them to stop working.

In real devices, the interface between different battery components changes during charging and discharging. This can lead to the formation of new materials during the motion of atoms. Developing model systems to study these materials and processes is challenging.

A recent study by the membrane growth laboratory group discovered that a multi-step growth process can introduce lithium into various oxide materials. By growing another metal oxide on a lithium-based film, the researchers created new oxides with lithium and a second metal. Understanding how these new oxides form can help researchers understand how the materials inside batteries change over time.

“We know that lithium can move through materials,” said Du, who has taken on increasing responsibility for the membrane growth lab and led the project. “But our results really show how lithium migration can lead to the formation of new oxides. These new oxides are promising model systems for studying how lithium moves in materials. solid materials, the fundamental work of developing the next generation of solid-state batteries.”

The research has mainly focused on incorporating lithium into titanium and tungsten oxide, but the team plans to expand their research. In particular, iron oxide and molybdenum have interesting potential applications for energy storage devices.

Understanding oxygen mixing

Tiffany Kaspar focuses on understanding how atoms move through materials, even when those materials are exposed to extreme conditions like in a nuclear reactor. Kaspar is a member of the Energy Frontiers Research Center of Reactor Basics of Understanding Subpole Transport (FUTURE).

For most materials, surfaces play an important role in determining how they interact with the world. It can have a major impact on the overall behavior of a material, making it essential for research. Their thinness and precise controllability make PNNL’s thin oxide films ideal for surface modeling of materials.

Kaspar and her collaborators studied how oxygen moves during the growth of chromium and iron oxide surface layers. For many materials, the addition of oxygen and the formation of oxides are part of their decomposition. This is called corrosion and is the process of forming rust on steel. Oxidation is a particularly difficult problem under extreme conditions, where the environment causes the material to degrade more rapidly. Understanding how oxygen moves through materials can help researchers develop improved, decay-resistant alloys.

To study oxygen in the material, the team first created a standard iron or chromium oxide film. They then switched the oxygen source to add traceable and specifically labeled oxygen atoms. Two separate layers of oxygen atoms allowed the team to study the movement of oxygen. If the oxygen atoms remained trapped in their original positions, the membrane would eventually have two separate layers—this is the usual understanding of membrane growth. That’s not what the team saw. Using 3D mapping, they discovered that oxygen from the upper and lower layers mixed in the material during film growth.

The researchers were able to determine how this happens at the atomic level. They found a mechanism by which newly added surface atoms “pull” atoms up from the layer below. The atoms then undergo a rotation like the rotation of the atoms inside the material. This means that what happens on the surface of the material does not stay on the surface.

The mixing mechanism identified in Kaspar’s work could be applied to more than just deposition of thin films and could work in the degradation of materials. Changes occurring at the surface have a deeper impact, altering the material in many of the layers below. Using Kaspar’s precisely labeled thin films, the team is exploring how radiation affects the motion of atoms, and they have additional plans to study the combined effects of radiation. and corrosion.

Chambers, who is continuing to work on the properties of complex oxide/semiconductor heterostructures for advanced electronic applications, said: “It will be interesting to see what happens next. for the group. “I’m extremely pleased to see younger members of the team I’ve mentored with over the years, like Yingge and Tiffany, increasingly take on leadership roles. The show is doing well.”

Provided by

Pacific Northwest National Laboratory

quote: Thin oxide films for developing model materials for semiconductors, sensors, and batteries (2023, March 22) retrieved March 23, 2023 from https://techxplore.com/news/2023- 03-thin-oxide-materials-semiconductors-sensors. html

This document is the subject for the collection of authors. Other than any fair dealing for private learning or research purposes, no part may be reproduced without written permission. The content provided is for informational purposes only.