Looking back at a waste product of the wood processing industry

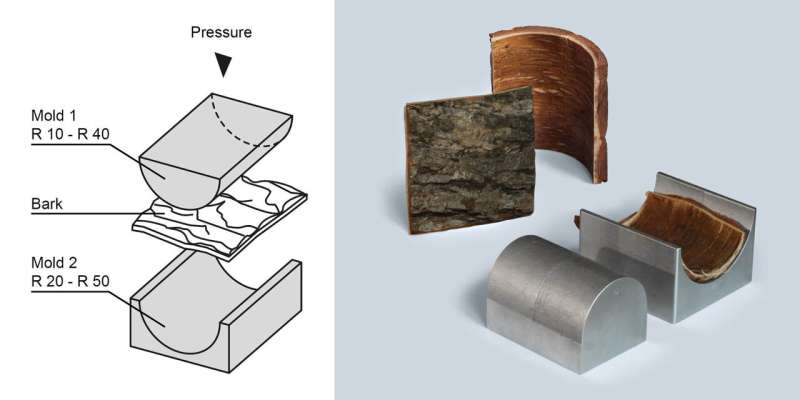

Production of bent bark details Credit: Dr. Charlett Wenig, PLEASE ONECC-BY 4.0

An interdisciplinary team of researchers from the Max Planck Institute for Colloids and Interfaces (MPICI) has studied how to use the natural properties of native bark to create a standardized product for long-term use. without additional adhesive. In doing so, they created sheets of bark by peeling and drying them by hot pressing, which can be used in interior design or furniture and packaging, such as through products. industrial output.

With this processing method, the natural resources of phloem can be further processed without adding artificial binders, such as adhesives and without consuming much energy. “The main advantage of ‘pure’ single-ingredient products is that there is no need to separate ingredients after they are used,” said Dr Charlett Wenig, first author of the study.

“Even if the structure of the raw material is changed, the basic building blocks remain the same and can therefore easily be used for further processing, such as obtaining chemicals or fibers, or fuel for energy production.”

It is a waste product of the wood and tree industry phloem available in large quantities. First, the bark must be peeled off the trunk and then dried. In the experiments, the scientists pressed the inside of the bark with a hydraulic press at a temperature of 90 degrees Celsius. They used bark from native tree species such as pine, conifer, birch and oak. After pressing, all bark panels manufactured in this way have a smooth surface equivalent to that of sanded wood. The mechanical properties of the board are comparable to the mechanical properties of the shelf board.

What’s new? In the past, pure bark chipboard was produced with the addition of formaldehyde-based resins or binders. As early as 1960, studies have shown that it is possible to produce bark boards without binders, but by using pieces of bark and through heavy processing. In the MPCI trials, the researchers are taking advantage of the bark’s natural structural properties.

The findings are published in the journal PLEASE ONE.

More information:

Charlett Wenig et al, Bark sheets without binders: An alternative application to waste materials, PLEASE ONE (2023). DOI: 10.1371/journal.pone.0280721

Provided by

Max Planck Society

quote: Rethinking a Woodworking Waste (2023, January 27) taken January 27, 2023 from https://techxplore.com/news/2023-01-rethinking-product-timber-industry .html

This document is the subject for the collection of authors. Other than any fair dealing for private learning or research purposes, no part may be reproduced without written permission. The content provided is for informational purposes only.