‘Lego-like’ universal connector makes assembling stretchable devices quick

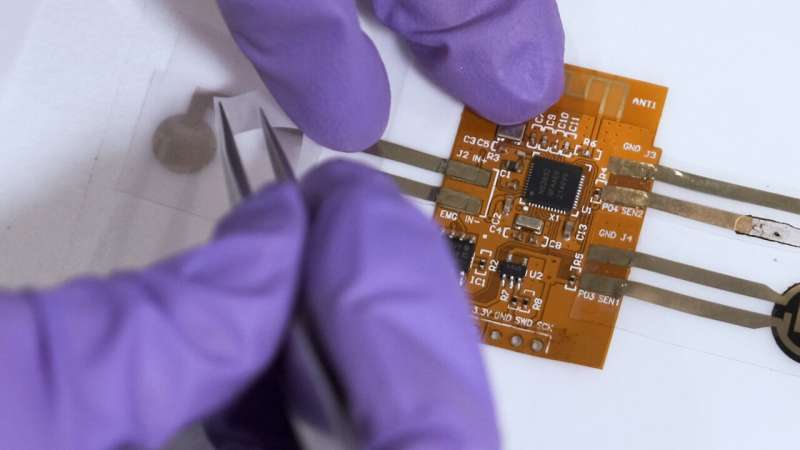

The BIND (two-phase, nano-dispersion interface) interface makes the assembly of scalable devices simple while providing excellent mechanical and electrical performance. Credit: NTU Singapore

An international team led by researchers from Nanyang Technological University, Singapore (NTU Singapore) has developed a universal connector for quick and simple assembly of stretchable devices, according to the report. “Lego-like” way.

Stretchable devices including soft robots and wearable healthcare devices are assembled using a number of different modules with different material properties—some soft. , some are hard and some are wrapped.

However, commercial pastes (glues), currently used to connect modules are generally not mechanically transmitted and Electronic signal sturdy when deformed or easily broken.

To create a device that works reliably, modular (interface) connectors must be custom built with sufficient strength to perform their intended tasks.

Building stretchable devices that are easily assembled without compromising their strength and reliability under pressure is a long-standing challenge that has limited their development.

Today, the team led by NTU reported in the journal Nature their answer to this challenge—BIND display (two-phase interface, nano-dispersion), making it simple to assemble scalable devices while providing excellent mechanical and electrical performance.

Like building structures with Lego blocks, high-performance stretchable devices can be assembled by simply pressing on any module with the BIND interface.

This convenient way to connect electronic modules could form the basis for future assembly of stretchable devices, where manufacturers “plug and play” parts by design. their.

When subjected to tensile tests, the modules were able to withstand a tensile force up to seven times their original length before breaking. Credit: NTU Singapore

Lead author of the study, Chen Xiaodong, Chair of the Professor of Materials Science and Engineering at NTU Singapore and Director of Science, Institute of Materials Engineering and Research, Agency for Science, Technology and Research (NTU Singapore) A*STAR), says: “Our ground-breaking innovation makes it very easy to create and use a stretchable device because it acts like a ‘universal connector’. ‘. Any electronic module with a BIND interface can be connected simply by pressing them together in less than 10 seconds. Furthermore, we eliminate the cumbersome process of building build custom interfaces for specific systems, which we believe will help accelerate the development of stretchable devices.”

This study aligns with the research pillar of the University’s five-year strategic plan NTU2025, which focuses on health and society as an area with the potential for significant intellectual and social impact.

Outstanding muscle and electrical stretchability

In the tests, the modules connected by the interface showed excellent performance. When subjected to tensile tests, the modules were able to withstand a tensile force up to seven times their original length before breaking. Furthermore, the power transmission of the modules remains as strong as 2.8 times the original length when stretched.

The BIND interface is also evaluated for interfacial toughness using the Standard Peeling Adhesion Test, where the adhesion strength between two modules is tested by pulling it apart with constant speed at 180°. For encapsulated modules, the researchers found this innovation to be 60 times stiffer than conventional connectors.

Dr Jiang Ying, a researcher at the NTU School of Materials Science & Engineering, said: “These impressive results demonstrate that our interface can be used to build wearable devices. or a highly functional and reliable soft robot, for example, it could be used in a high-quality wearable fitness tracker where the user can stretch, gesture and move in whatever way is most comfortable for them without affecting the device’s ability to receive and monitor physiological signals.”

To demonstrate the feasibility of use in real-world applications, the team built the stretchable devices using the BIND interface and tested them on mouse and human skin models.

When attached to mouse models, recordings from the monitor can stretch to show reliable signal quality despite disturbances in the wiring, such as touches and jerks. When applied to human skin, the device collected high-quality electromyography (EMG) signals to measure the electrical activity generated in muscles during muscle contraction and relaxation, even while underwater.

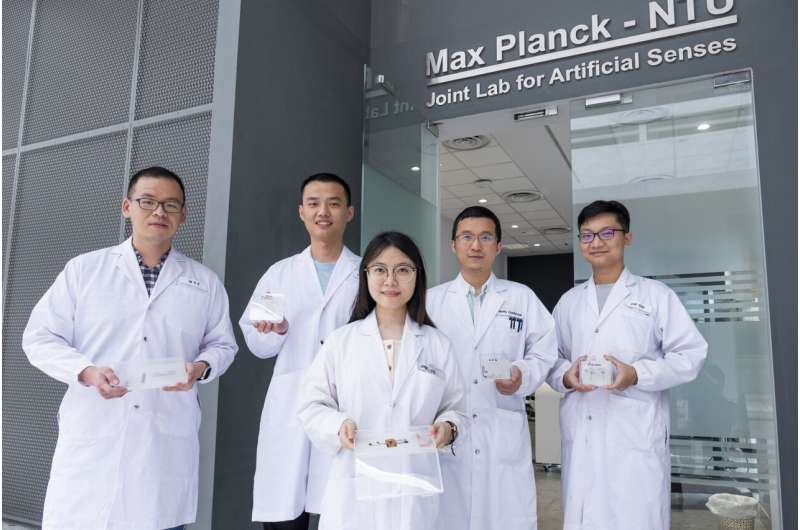

Members of the NTU Singapore team behind the BIND interface. Credit: NTU Singapore

How the interface works

To develop the BIND interface, the researchers thermally vaporized metal nanoparticles (gold or silver) to form a strong penetrating nanostructure inside a soft thermoplastic commonly used in electronics. stretchy electronics (styrene-ethylene-butylene-styrene).

The resulting nanostructure provides both continuous electrical and mechanical paths, allowing modules with BIND connectivity to maintain strength even under deformation.

Giving his opinion as an expert not involved in the research, Professor Takao Someya from the Department of Electrical and Electronic Engineering at the University of Tokyo said: “This study represents an important achievement. in developing an excellent elastic, stress-free electrical bonding technique, focusing on the bonding between modules of different stiffness, thus reducing noise. industry of scalable devices is expected with the establishment of an industrial scale-able high-throughput production method.”

Commenting as an independent expert, Professor Shlomo Magdassi from the Institute of Chemistry at the Hebrew University of Jerusalem said: “This new universal and simple plug-and-play method led by Professor Chen Xiaodong and his team’s development is significant as it will allow the rapid combination of different components by simple pressing to form devices of various functions and complexity, accelerating the development of the field of elastic electronics.”

An international patent has been filed for the innovation. As for the next steps, the team is developing a more efficient printing technology to expand the selection of materials and the ultimate application of this innovation, to accelerate the translation from laboratory to design. and produce products.

More information:

Xiaodong Chen, A universal interface for plug-and-play assembly of stretchable devices, Nature (2023). DOI: 10.1038/s41586-022-05579-z. www.nature.com/articles/s41586-022-05579-z

Provided by

Nayang Technological University

quote: ‘Lego-like’ universal connector that makes assembly of stretch devices quick (2023, 15 February) retrieved 15 February 2023 from https://techxplore.com/news /2023-02-lego-like-universal-connector-stretchable-devices .html

This document is the subject for the collection of authors. Other than any fair dealing for private learning or research purposes, no part may be reproduced without written permission. The content provided is for informational purposes only.