Fully immersive virtual simulation can enhance industrial accident prevention

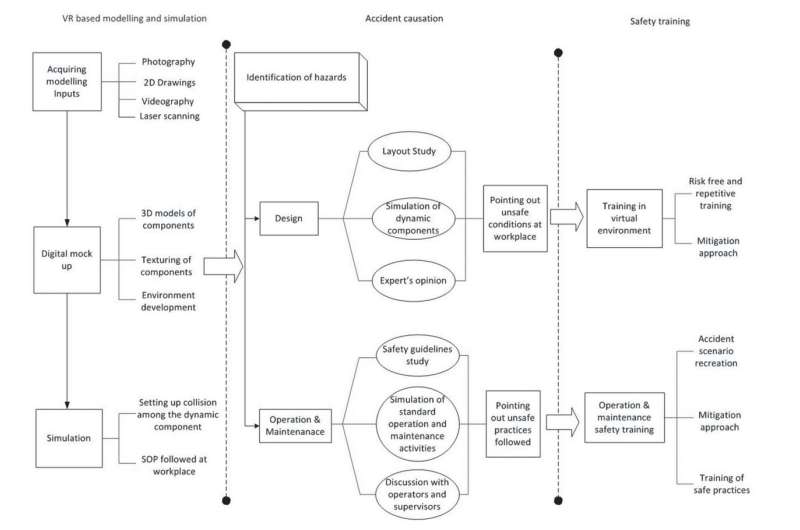

Structure of VR-ACM. Quoted from Dhalmahapatra et al., (2020). Credit: https://osuva.uwasa.fi/handle/10024/14553

Industries must adopt 3D modeling with fully immersive virtual simulations in their occupational safety management systems. This will help them optimize accident prevention, according to a new study from the University of Vaasa, Finland.

The benefits of VR (Virtual Reality) technology stem from its ability to present a replica of any facility, situation or process used for assessment or training. Furthermore, when used effectively, VR can reduce the operational risks of companies. It can provide users with better work practices and improved hazard awareness through guidance related to the product, process or work environment.

“Such features are important for accident prevention because traditional industrial safety training methods are mostly monotonous and boring without the full interaction of the tasks involved. to stimulate learning and retention. This is especially problematic when the current generation of employees is familiar with games, devices, and programs. Learning in this area is more acceptable to them.” , Ebo Kwegyir-Afful, who will publicly defend Doctoral thesis at Vaasa University, on Friday, 28order of October.

Ebo Kwegyir-Afful makes these claims based on statistical evidence of experiments conducted at the Technobothnia research center in Vaasa from 2017–2022. The experiments were designed to demonstrate VR’s potential in preventing accidents during manufacturing and maintenance operations at the facility’s conceptual stages. Two industrial 3D models were used: lithium-ion battery manufacturing plant and a gas power plant.

According to the test results, VR can advance prominent areas of industrial accident prevention: safety training, hazard identification and risk assessment (HIRA), and emergency preparation and response initiatives (EPR). These are the three core areas of industrial accidents Prevent according to ISO 45001:2018 standard.

“When used appropriately, VR can enable industries to achieve significant safety countermeasures by enhancing or improving safety training, HIRA, and response initiatives.” emergency response and preparedness to be more interactive and engaging. With these measurements, the entire organization’s safety management system becomes more effective.” Ebo said based on his doctoral research.

An important part of the HIRA process includes controlling and minimizing hazards that can be identified to be remedied during the design of the plant model. Finally, the study emphasizes safety countermeasures at the conceptual stage of the plant.

Dissertation (in Finnish): osuva.uwasa.fi/handle/10024/14553

Provided by

University of Vaasa

Quote: Fully immersive virtual simulations that can promote industrial accident prevention (2022, October 27) retrieved October 27, 2022 from https://techxplore.com/news/2022-10 -ly-immersive-virtual-simulation-boost.html

This document is the subject for the collection of authors. Apart from any fair dealing for personal study or research purposes, no part may be reproduced without written permission. The content provided is for informational purposes only.