An improved EV motor used by Lamborghini, McLaren and Ferrari is being mass-produced by Mercedes

Auto enthusiasts lament the commodification of propulsion. Once the gasheads have chosen one BMW car because of its straight six or one sound Mercedes-AMG for its thunderous V8 engine. Now many people believe that the difference is rapidly diminishing. Tram can deliver crazy, silent thrust, but people often complain that they’re virtually indistinguishable in terms of their powertrain characteristics.

Automakers are also worried about this. Their engineering DNA is less obvious in the electric vehicle age, making them more dependent on design, brand strength and other types of technology to differentiate their vehicles and retain customers. There is no point in trying to overcome competition for power when speed is fastest Tesla And Lucid There’s already more than you can deploy on public roads. More is not better when you already have too much.

But soon there will be a choice: between tradition radial engine has powered almost every electric vehicle to date and something completely different.

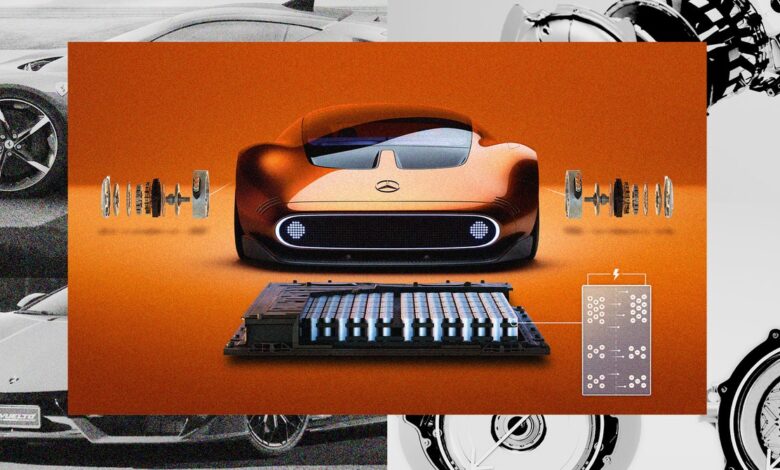

Axial motors don’t necessarily deliver more power, but they are so much lighter and smaller that their proponents say they have the potential to transform almost every other important measure of a vehicle’s performance. electric vehicles — and the entire architecture of a car designed around them.

By mounting axial flow motor wheels, the spaces in the car’s body currently occupied by the engine can be largely vacated, clearing the way for more batteries, people or stuff, and allowing for the kind of cutting-edge design that Electric vehicles have long been promised but never delivered.

More importantly, this new motor design could help address the growing public backlash against expensive and overpowered electric vehicles. They can reduce the weight of a typical electric vehicle by about 200 kg (440 pounds)—half in the motor itself and half through the combined mass effect, allowing you to reduce the weight of other systems like batteries and brakes. .

By sending mass into a virtuous downward spiral, automakers can increase range, reduce costs, and perhaps even maintain the nimble handling of their cars. lightweight, which auto enthusiasts also worry could disappear with the advent of electric vehicles.

Throughput capacity

This principle is not new. The axial motor was first demonstrated by Michael Faraday in 1821, but during the next two centuries, no one found a way to reliably mass-produce it.

However, British academic Tim Woolmer likes a challenge. He devoted his Oxford doctorate to designing optimal motors for electric cars. He decided that an axial flux motor would make more sense than the nearly ubiquitous and easily mass-produced radial flux design. But the design he chose not only had barely made it out of the lab for nearly 200 years, but there was no market for it when he started in 2005: GM’s EV1 has been canned for a long time, and Tesla Roadster There are still three years left.

In a “pancake” motor with axial flux, the stator (stationary part of the electric motor) and the rotor are discs, located next to each other less than a millimeter apart, the flux flows through the stator in an axial or parallel direction. parallel to the axis, and acts on the permanent magnets on the rotors on both sides to rotate them.