A hackable, multifunctional and modular extrusion 3D printer for soft materials

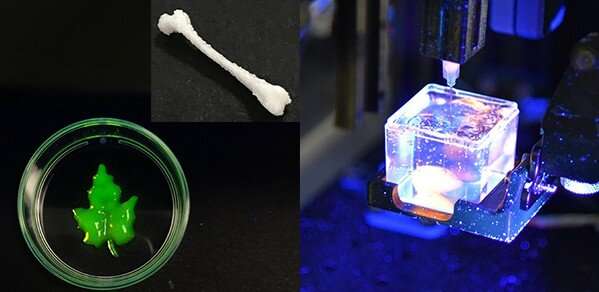

Complex designs are possible using ‘Printer.HM’. From left, leaf truss with hydrogel made of cellulose; a femur model printed with bioceramic hydrogel; Print embedded in a support bath. Credit: University of Cambridge

Researchers have developed a multifunctional and hackable 3D printer for affordable soft materials and an open design. This technology has the potential to unleash further innovation in diverse fields, such as tissue engineering, soft robotics, food and environmentally friendly materials handling — supporting the creation of unprecedented design.

Printer.HM, as it is known, is a highly customizable extrusion based 3D printer to compete with commercial 3D bioprinters. It is capable of accepting various geometric inputs — including computer-aided design (CAD) models, coordinates, equations, and images — to produce prints with individual. The evolution of this multi-printhead system — built on a hackable robotic arm and providing multi-function in one platform via heating and ultraviolet (UV) modules — is the product brainchild of researchers from the Faculty of Engineering, University of Cambridge and the Center for Nanoscience, University of Cambridge, in collaboration with the Universities of Macau and Oxford. Details of their approach to affordable printing are reported in the journal Scientific reports.

In addition to providing excellent print compatibility with a wide range of liquids and soft materialA multitude of activities can be performed, including:

- Liquid preparation

- Print many materials

- Print at variable speed

- Embedded printing (creates a free-form and overhanging structure)

- Print not flat

- Receive and book application.

With optional UV and heating modules, the printability of thermally reactive and photopolymerized hydrogels can be tuned, and they are used in a wide range of biomedical applications including drug delivery, tissue engineering and heal wounds.

Printer.HM provides users with design freedom and the ability to customize the print path to produce prints with distinctive characteristics. These are: simple patterns (coordinates); print a stroke (equation); 3D design (G-code); and customizable 2D textures (images), which can later be easily converted to print without creating a CAD model. The ability to customize the print is particularly useful for soft robotics applications, as demonstrated by the researchers creating a soft transform system made of pH-responsive hydrogels.

The researchers used Printer.HM to create a 2D sketch of a floral pattern, which then expanded and turned into a 3D flower within four minutes. And this is just the beginning; Because the control program is completely hackable, users can reconfigure the setup and extend its functions to previously unattainable 3D printed designs. The researchers also demonstrated Printer.HM’s potential in creating sophisticated tissue anatomy, by successfully creating a model of the respiratory system with lungs and trachea, made of alginate ink and printed inside. a support bath.

Dr. Iek Man Lei, first author and Assistant Professor at the University of Macau, is a former Ph. student from the Biointerface Research Group at Cambridge.

Dr Lei said, “Printer.HM’s versatile functions, coupled with its open design and affordability (total cost between £900 and £1,900), make it an option. Trusted for the future of 3D printing innovation using soft, biological and architectural sustainable materials. modular design allow research community to extend Printer.HM’s functions even further, opening up the possibility of countless new designs. Other benefits include printhead compatibility with smaller sized syringes desired in small scale bio applications and ease of use for those with no CAD experience to customize print lines. using image input – this is particularly beneficial for controlling the variable behaviors of stimulus-responsive hydrogels. “

She added, “Printer.HM has the potential to open the door to innovative 3D printing in diverse fields, such as tissue engineering, soft robot, food, and environmentally friendly material processing. Open design, affordability, improved customizability and all-in-one functions will benefit the do-it-yourself research community, providing a viable alternative to printers existing trade. ”

Iek Man Lei et al, A modular, multifunctional and hackable extrusion 3D printer for soft materials, Scientific reports (In 2022). DOI: 10.1038 / s41598-022-16008-6

Provided by

University of Cambridge

Quote: A modular, multifunctional and hackable extrusion 3D printer for soft materials (2022, October 27) retrieved October 27, 2022 from https://techxplore.com/news/2022 -10-hackable-multi-func-modular-extorated -3d.html

This document is the subject for the collection of authors. Apart from any fair dealing for personal study or research purposes, no part may be reproduced without written permission. The content provided is for informational purposes only.